Often ignored, silver plays a crucial role in modern nuclear energy, but practically unknown is silver’s new critical role emerging from the power plants of the future, fusion.

The importance of silver’s thermal and electrical conductivity, as well as its reflectivity, can not be understated. Silver’s best qualities are being exploited to make the new generation of energy possible.

Fusion power is the long-awaited upgrade to fission and may be coming just in time as Artificial Intelligence is increasing electricity demands on the grid, and this trend is unlikely to be abated.

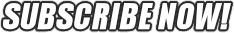

Announced late December 2024, Commonwealth Fusion Systems unveiled plans for the world’s first grid-scale commercial fusion power plant that will be built in Chesterfield County, Virginia, and expected to come online by 2030.

The new fusion power plant, named ARC, will generate about 400 megawatts of clean, carbon-free electricity for about 150,000 homes. ARC is positioning the U.S. to lead the world in harnessing a new form of safe and reliable energy that could prove critical for economic growth and national security.

Around the world, fusion power is being adopted as the next leap for mankind.

ITER is the international nuclear fusion research and engineering megaproject where the EU, China, India, Japan, Korea, Russia ,and the US have come together to complete the world’s largest fusion reactor.

More than 130 experimental nuclear fusion reactors, both public and private, are in operation, being built, or planned in 50 countries across the globe, according to a December 2022 report by the International Atomic Energy Agency (IAEA).

About 90 are in operation.

Most of them are based on the ITER core designs, which, for various components, rely on silver’s exceptional properties to get the job done.

Belo,w we explore some of the ways we found that silver is being used for the construction of these monumental human undertakings of science. There are several components of the fusion design that rely on silver, which is putting a strain on the overall supply.

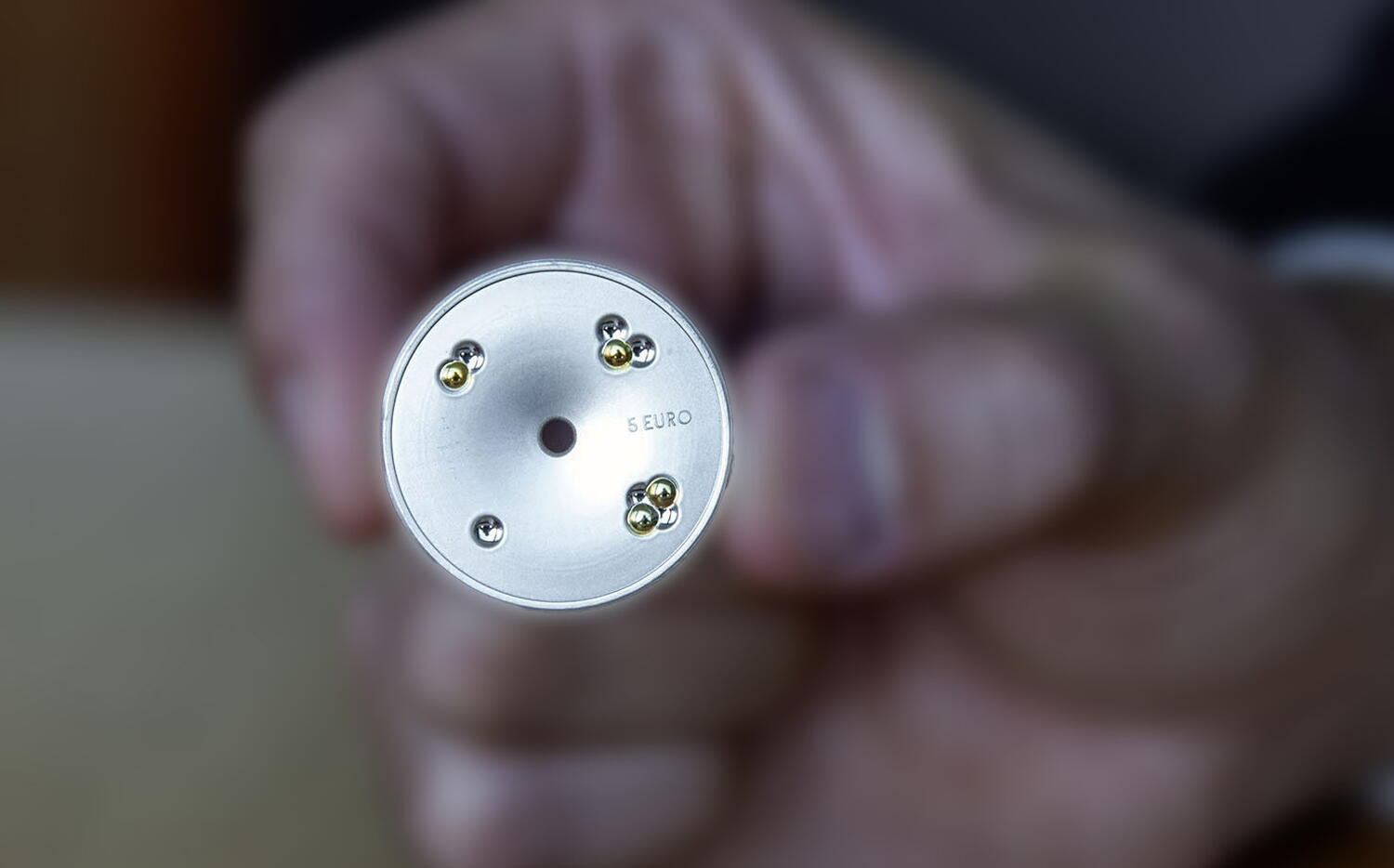

High Temperature Superconducting (HST) Tape

ITER’s magnets—toroidal field (TF), poloidal field (PF), central solenoid (CS), and correction coils (CC)—require current leads to deliver up to 68 kA from room-temperature power supplies to the 4.5 K superconducting environment. HTS current leads reduce heat load to the cryogenic system compared to traditional copper leads, cutting refrigeration power by about two-thirds. Silver is integral to the HTS tapes within these leads.

According to the UK fusion startup Tokamak Energy, magnetic fields are used in the tokamak to confine and control the electrically charged plasma that constitutes the fusion reactor’s “fuel”.

High-temperature superconducting (HTS) tape is generally used in strong electromagnets that are used to confine plasma in magnetic-confinement fusion reactors.

The magnetic fields are generated by passing large electrical currents around arrays of electromagnet coils that circle the plasma, and those magnets are wound from what Tokamak Energy calls “groundbreaking” HTS tapes.

Faraday Factory has been producing HTS tapes since 2012, and Coherent says that demand for the tape is expected to increase by a factor of ten between now and 2027.

Several manufacturing steps are needed to make the tape, with the Japanese firm using ion beam assisted deposition (IBAD), pulsed laser deposition (PLD), silver magnetron sputtering, and copper electrochemical plating.

Silver magnetron sputtering is a physical vapor deposition (PVD) technique used to deposit thin films of silver onto a substrate. It’s a process commonly employed in industries like electronics, optics, and materials science to create coatings with specific properties, such as reflectivity, conductivity, or corrosion resistance.

Here’s how it works in simple terms:

In a vacuum chamber, a silver target (the source material) is bombarded with high-energy ions, typically from a plasma of an inert gas like argon. A magnetic field, generated by a magnetron, confines the plasma near the target, enhancing the efficiency of the process. This bombardment knocks silver atoms loose from the target, and they travel through the vacuum until they land on the substrate, forming a thin, uniform layer.

The “magnetron” part refers to the use of magnets to trap electrons, which increases the ionization of the gas and makes the sputtering more effective, even at lower pressures.

Silver is often chosen for its excellent electrical and thermal conductivity, as well as its reflective properties, making it useful for things like mirrors, solar cells, or conductive coatings.

The Silver Shields

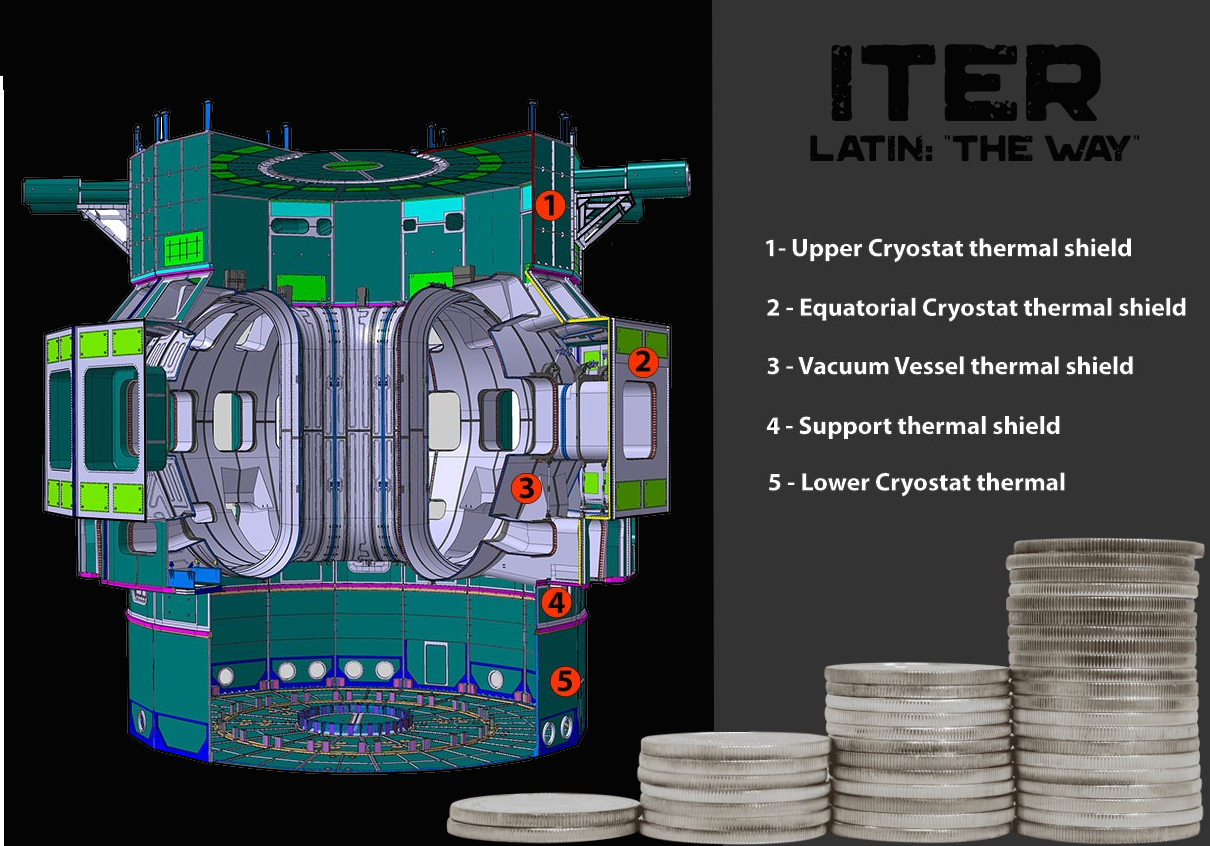

Another major and critical component of the fusion design is the thermal shields.

Thermal shields are installed to limit the heating of the superconducting magnets, in particular due to radiation from the cryostat and the vacuum vessel.

Silver has the highest thermal conductivity of all known metals (429 W/m•K). For this reason, silver has been chosen as the element best suited to ensure the safety of the operation.

Components of the Tokamak are coated in a thin layer of silver that covers the entire surface.

Silver is critical to its design because it raises an obstacle against the thermal radiation in the form of electromagnetic waves.

The plating of the vacuum vessel thermal shield was done in electrolysis baths that required 5 tons of pure silver. Approximately 800 kilos went into the coating of the 2,000 square meters of vacuum vessel thermal shield.

A real-size mockup for a large section of vacuum vessel thermal shield is undergoing the step-by-step process of silver coating.

This work, part of Korea’s contribution to ITER, has been conducted by companies like SFA Engineering Corp in Changwon, South Korea.

The vacuum vessel thermal shield comprises nine 40° sectors. Sector #6 is pictured here, ready to be packed and shipped to ITER.

As a secondary, while being constructed, silver is also integrated into shielding for sensitive electronics to mitigate electromagnetic interference (EMI) or radiation effects.

Superconducting Magnets

Silver is used as a matrix material in niobium-tin (Nb₃Sn) and niobium-titanium (Nb-Ti) superconducting cables. The silver matrix provides stability by conducting current during transient events (e.g., quenches) and enhances mechanical strength.

Electrical Systems

The issue with the busbars in the ITER project involved the need for effective electrical insulation capable of withstanding the high voltage and harsh operational conditions within the superconducting environment.

The challenge was to ensure that the insulation provided uniform coverage, minimized the risk of electrical faults, and could maintain long-term reliability under extreme conditions.

This led to the use of James Cropper’s silver-coated nylon and copper-nickel carbon nonwoven veils to enhance the insulation’s performance and durability.

Silver-coated nylon and copper-nickel carbon were chosen for the ITER busbars due to their excellent electrical conductivity, corrosion resistance, and ability to provide effective electromagnetic shielding.

The silver coating on nylon enhances the material’s conductivity and resistance to oxidation, while the copper-nickel carbon veil offers durability and high thermal and electrical conductivity. These properties were essential to ensure reliable and uniform insulation capable of withstanding the extreme operational conditions within the superconducting environment of ITER.

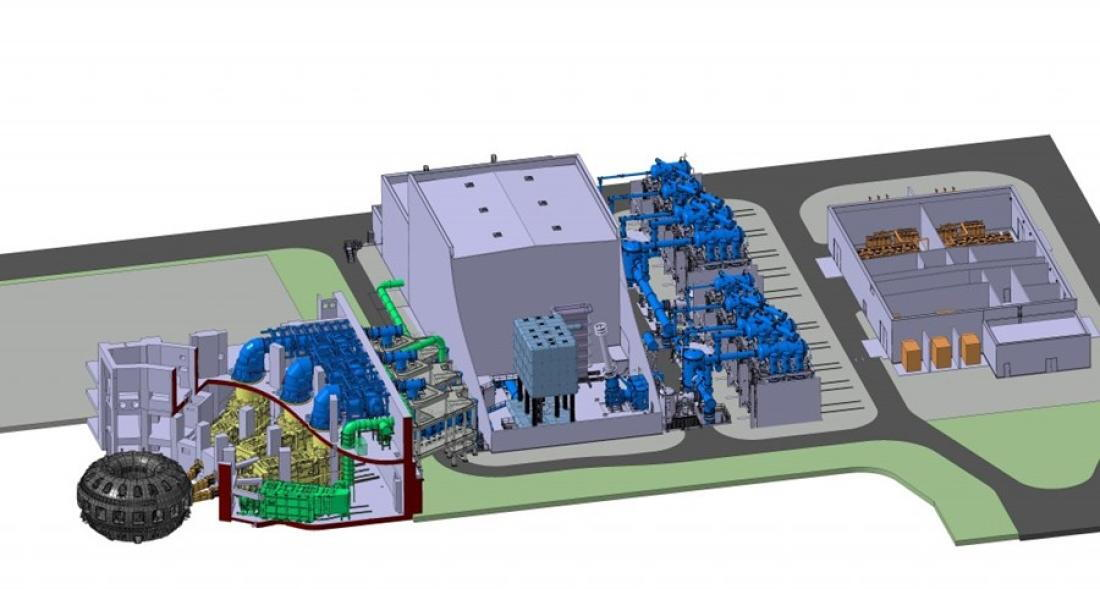

Neutral Beam Power Supply

Silver contacts and connectors are being used in ITER’s high-power systems for efficient energy transfer.

Hosted across two buildings and an outdoor technical area (centre and right), the ITER neutral beam power supply installation comprises an array of transformers, generators, rectifiers, inverters, and other exotic electrical devices designed to feed at 1 MV ultra high voltage to the injectors.

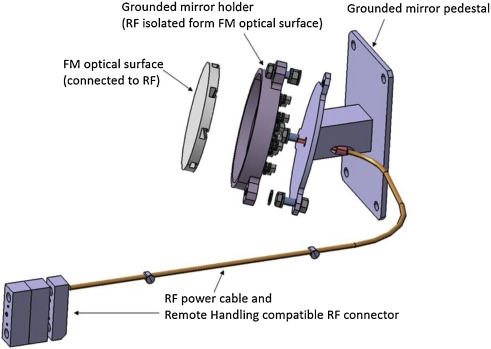

Optical Diagnostic Systems

One of the first optical diagnostic systems in the ITER tokamak chamber, where the plasma cleaning system has to be implemented, is the Visible Spectroscopy Reference System (55.E6.VSRS), which will be used for line averaged measurements of the visible continuum emission of the core plasma.

This system utilizes large-scale collecting mirrors for the in-vessel collection system. These mirrors are located out of line with the vision of fusion plasma. They rely on a high-reflective silver-based coating.

Transmission lines use coaxial type cables in all cases that are made with copper and partially coated with silver.

High-Temperature Brazing Alloys

Silver-based alloys (e.g., Ag-Cu) are used to join components in the vacuum vessel, cooling systems, and magnets, ensuring strong, leak-tight, and thermally conductive joints.

Thermal Management

Silver-filled thermal pastes or pads may be used to enhance heat transfer in high-heat-flux areas, such as between plasma-facing components and auxiliary cooling systems

Vacuum Systems

Silver’s low outgassing properties make it suitable for ultra-high vacuum seals in the vacuum vessel and diagnostic ports.

There are no alternatives to being the best, and as demonstrated, being the best means silver is called on for making possible humanity’s most incredible feats of advanced engineering.

Silver will continue to enhance humanity’s future prosperity as long as it’s available, but this energy-dependent future for some countries may not be realized should the silver supply crisis continue unabated.

To ensure the United States has its necessary supply, designating silver as a critical material is more important than ever!

Shared by Golden State Mint on GoldenStateMint.com